Urbanization has led to rapid growth and development, bringing with it challenges such as flooding, water scarcity, and environmental degradation. To address these issues, the concept of sponge cities has emerged as an innovative solution for sustainable urban development. Sponge cities integrate green infrastructure, water management, and environmental conservation to create urban spaces that can absorb, store, and reuse rainwater, helping to mitigate flooding and improve water quality.

At the core of this sustainable urban development are eco-component moulds and sponge city component moulds, which play a critical role in manufacturing the structures and systems needed for these green initiatives. This article explores how these moulds contribute to sustainable construction and help shape the future of eco-friendly urban planning.

What Are Sponge Cities?

A sponge city is an urban area designed to absorb and manage stormwater through a combination of permeable surfaces, green infrastructure, and advanced water treatment technologies. The goal is to replicate the natural water cycle by capturing rainwater, filtering it, and reusing it for various purposes, including irrigation, recreational water bodies, and even drinking water in some cases.

Key features of sponge cities include:

- Permeable Pavements: Surfaces that allow water to infiltrate into the ground instead of running off into drains.

- Green Spaces and Parks: Areas that help absorb excess water and reduce the heat island effect.

- Rainwater Harvesting Systems: Technologies that collect and store rainwater for later use.

- Water Retention and Detention Systems: Structures designed to manage and store stormwater, reducing flooding risks.

The Role of Eco-Component and Sponge City Component Moulds

To build the structures necessary for sponge cities, manufacturers rely on specialized eco-component moulds and sponge city component moulds. These moulds are designed to create a wide range of products that contribute to sustainable urban development, including permeable paving blocks, water retention systems, and eco-friendly drainage solutions. The use of these moulds ensures that each component is accurately shaped, durable, and functional.

1. Eco-Component Moulds

Eco-component moulds are used to manufacture various building components made from sustainable materials that support environmental conservation. These components include:

- Permeable Pavement Blocks: Moulds are used to create pavement blocks that allow water to pass through, reducing surface runoff and promoting groundwater recharge.

- Green Wall Panels: These panels are used in urban green spaces and vertical gardens, improving air quality and enhancing the aesthetic appeal of cities.

- Eco-Bricks and Sustainable Building Materials: Eco-component moulds help produce bricks and other construction materials made from recycled or sustainable materials, contributing to eco-friendly building practices.

2. Sponge City Component Moulds

Sponge city component moulds are specialized for creating structures that are essential for managing water in sponge cities. These components are designed to capture, store, and manage rainwater effectively, reducing the risk of flooding and promoting water reuse. Key products made using sponge city component moulds include:

- Stormwater Detention Tanks: These tanks are designed to store excess rainwater during heavy storms, preventing flooding and allowing for controlled release or reuse of the water.

- Infiltration Trenches: Moulds are used to create trenches that allow rainwater to flow into the ground, replenishing groundwater levels and reducing runoff.

- Green Infrastructure Elements: This includes permeable paving, bio-retention basins, and vegetated swales that help absorb water and reduce the load on traditional drainage systems.

Advanced Manufacturing Techniques for Sustainable Moulds

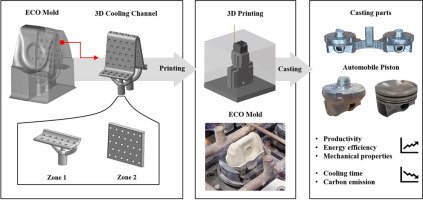

The production of eco-component and sponge city component moulds involves advanced manufacturing techniques that ensure precision, durability, and environmental sustainability. These techniques are critical for producing high-quality components that can withstand the demands of urban environments while supporting sustainable urban development.

1. Precision Design for High-Performance Components

One of the primary benefits of using eco-component and sponge city component moulds is the precision they offer. Using computer-aided design (CAD) software, manufacturers can design moulds to meet specific project requirements, ensuring that each component is produced with the correct dimensions and features. Precision design guarantees that the finished components fit seamlessly into the infrastructure of sponge cities and perform optimally in terms of water absorption, retention, and filtration.

2. Sustainable Materials for Mould Production

The manufacturing of eco-component and sponge city component moulds utilizes sustainable materials to minimize environmental impact. High-strength steel and recycled metals are often used to create durable and long-lasting moulds. Additionally, moulds are designed to be reusable, reducing the need for frequent replacements and promoting a circular economy.

3. Hydraulic and Automated Systems

Incorporating hydraulic systems and automated machinery into the manufacturing process increases efficiency and reduces labor costs. Hydraulic systems are often used to open and close moulds quickly and precisely, while automated machinery can handle repetitive tasks such as positioning reinforcement steel or monitoring the curing process.

These technologies allow manufacturers to produce large volumes of high-quality components in less time, which is essential for meeting the growing demand for sustainable infrastructure solutions in urban development.

4. Customization for Diverse Urban Needs

Eco-component and sponge city component moulds can be customized to create components of various sizes, shapes, and configurations. This flexibility ensures that the components are adaptable to different urban environments and specific project needs. Whether it’s designing permeable pavers for walkways or creating water retention tanks for stormwater management, custom moulds ensure that each component is optimized for its intended function.

5. Use of Eco-Friendly Materials in Component Production

The moulds themselves can be designed to accommodate eco-friendly materials such as recycled plastics, sustainable concrete, and green composites. These materials further contribute to the sustainability of the construction process and the long-term performance of the components produced. For example, using recycled concrete in the production of eco-components helps reduce the carbon footprint of urban construction projects.

Benefits of Eco-Component and Sponge City Component Moulds

The use of eco-component and sponge city component moulds offers several benefits for both manufacturers and urban planners looking to incorporate sustainable practices into their development projects.

1. Enhanced Sustainability

By using sustainable materials and advanced manufacturing techniques, these moulds help create components that contribute to environmentally responsible construction practices. The components produced are designed to promote water conservation, reduce pollution, and enhance green spaces, all of which are essential for creating sustainable urban environments.

2. Improved Water Management

Components made from sponge city component moulds help improve water management in urban areas by capturing, filtering, and reusing rainwater. This reduces the strain on traditional drainage systems, minimizes the risk of flooding, and ensures that water resources are used efficiently.

3. Cost-Effectiveness

Although the initial investment in sustainable moulds may be higher, the long-term savings are substantial. By reducing the need for repairs and replacements, and promoting efficient water management, eco-components and sponge city components help lower maintenance costs and improve the durability of urban infrastructure.

4. Customization for Tailored Solutions

The ability to customize eco-component and sponge city component moulds ensures that they can meet the unique needs of any project. This flexibility allows for the design of solutions that are tailored to the specific environmental, social, and economic challenges of the area.

5. Support for Green Urban Planning

The use of these moulds is central to the success of green urban planning initiatives. By producing high-quality, sustainable components, these moulds help shape cities that are better equipped to handle climate change, reduce their environmental footprint, and provide a higher quality of life for residents.

Conclusion

The series of eco-component and sponge city component moulds represent a significant advancement in sustainable urban development. By providing the means to create high-quality, functional, and durable components for water management and green infrastructure, these moulds play a crucial role in transforming urban spaces into sponge cities that are more resilient to flooding and environmental challenges. Through advanced manufacturing techniques, the production of these components not only supports sustainable practices but also contributes to the long-term health and well-being of urban communities.